We develop technologies for live monitoring of particle flows in chemical and food production plants.

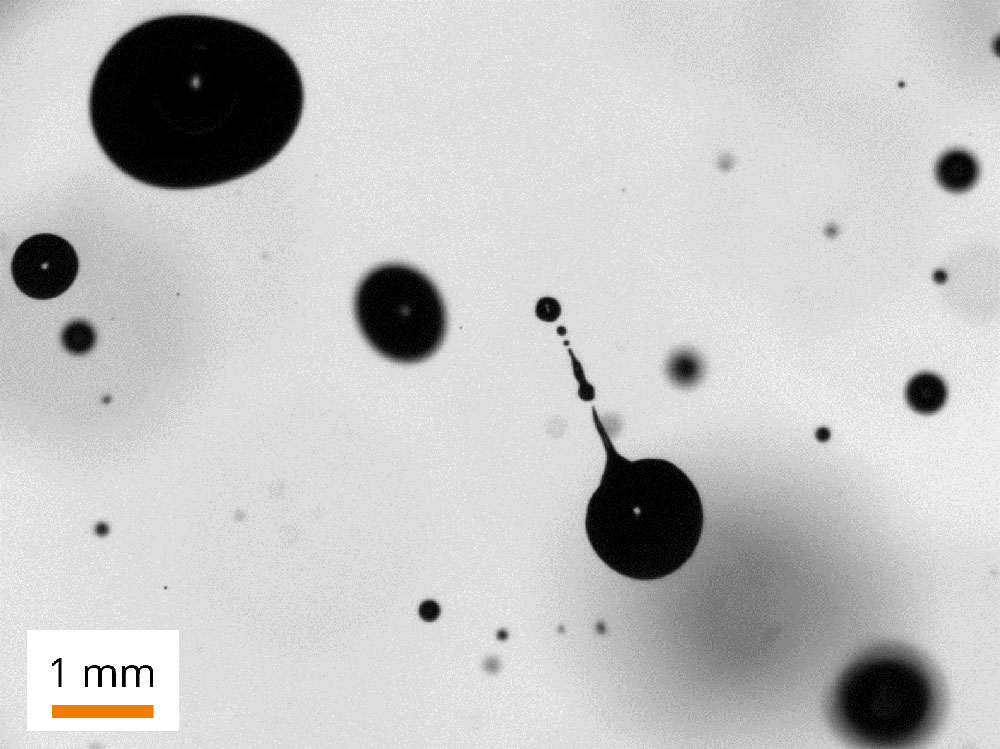

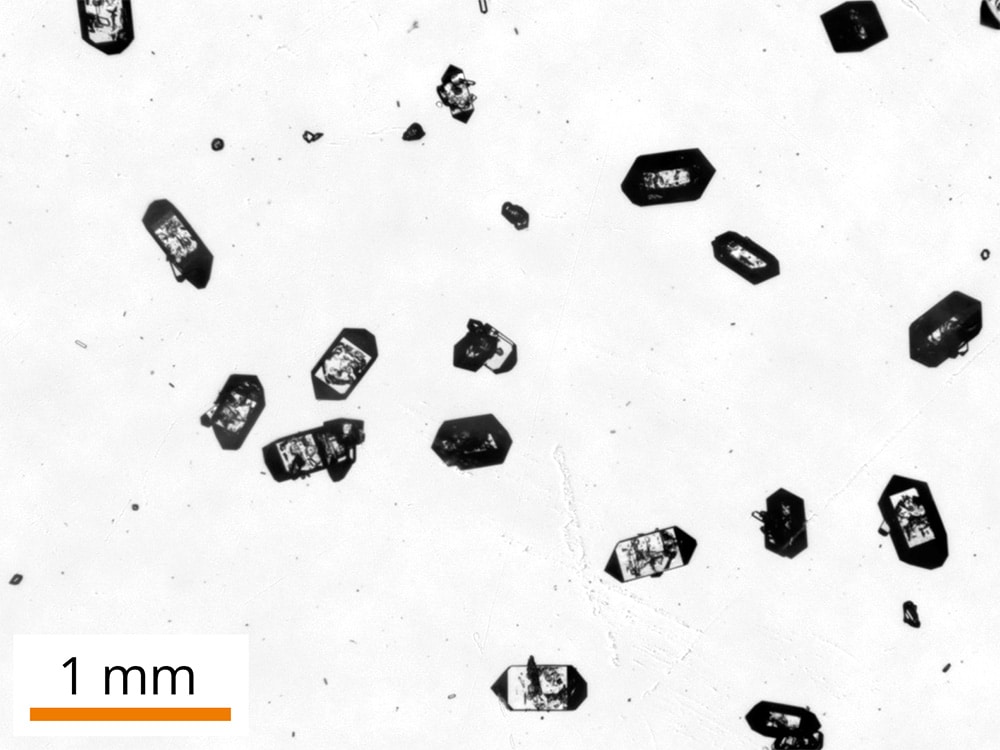

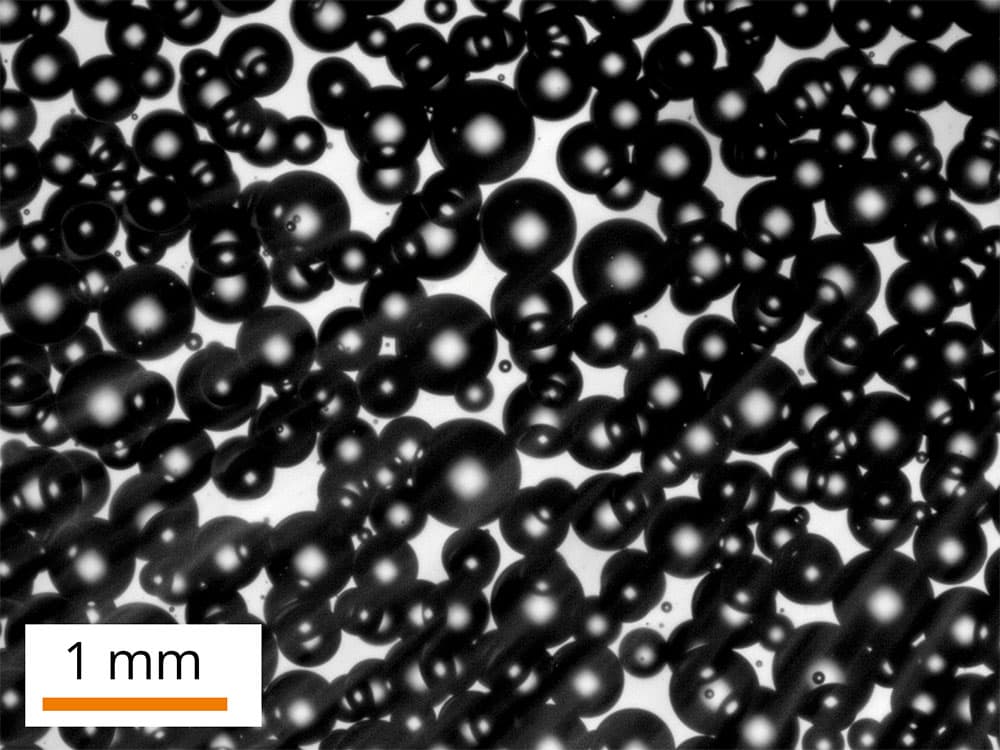

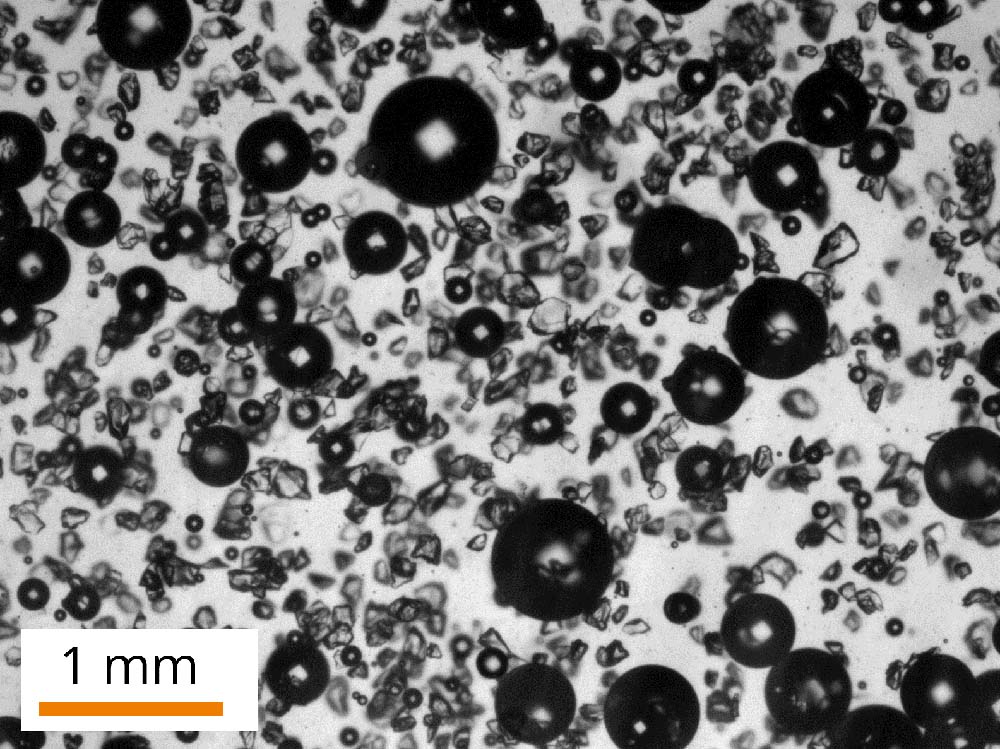

High-resolution, AI-based, image-based microscopy is used to precisely record the size and shape of particles, bubbles, droplets, and crystals.

Capture what would otherwise remain hidden

INNOVATION FROM THE HEART OF THE PALATINATE

SWR visits Inline Process Solutions

For a better understanding of your process

Discover how real-time monitoring

makes your facilities more efficient and safer.

The right sensor technology for your application

Benefit from excellent image quality and easy integration:

our inline sensors provide you with unique images from inside your equipment. For real-time process data and data-based process optimisation.

Choose from different product groups to suit your application. Flow sensors for pipes and insertion sensors with one-sided process access are available.

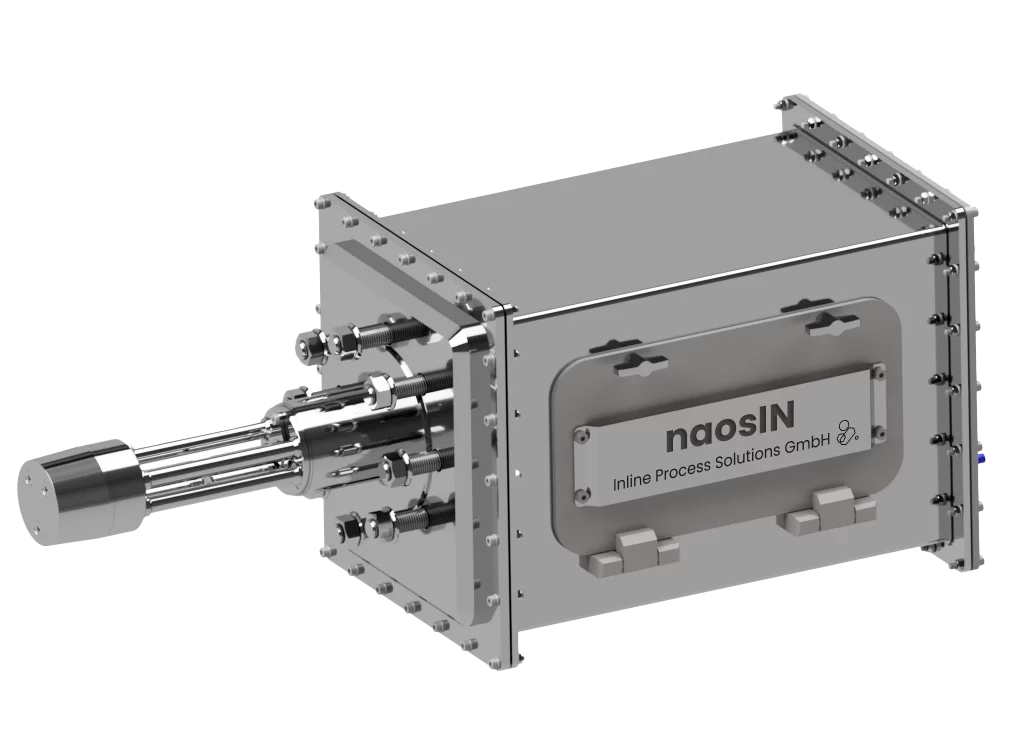

With naosIN, we are setting new standards: the sensor technology enables you to detect droplets and small particles in gas streams inline. Measurements are taken at the point of action – directly in the apparatus or gas pipe.

The sensor technology is used for the design of separators, nozzles and filters, for controlling entrainment and in spray drying.

arkturIN offers a comprehensive solution for the precise real-time detection of solids, bubbles and droplets in liquids. Measurements are taken at the point of interest – directly in the vessel or pipeline. The sensor technology is used in mixing processes, hydrogen applications and various solid-liquid systems, including crystallisation, precipitation and extraction.

alnairON is the all-rounder for pipelines: detect solids, bubbles or droplets in real time and with excellent recording quality. Thanks to its specific optical design, precise measurements are possible even at high suspension densities. The sensor technology is used in various solid-liquid systems, including crystallisation, precipitation and extraction.

denebON is our answer to challenging process conditions: the sensor technology enables to detect bubbles in liquid flows in potentially explosive environments. Thanks to its design in accordance with DGRL, precise measurements up to 40 bar are possible. The sensor technology is used in gas-liquid multiphase systems such as absorption, in energy technology and synthesis gas applications.

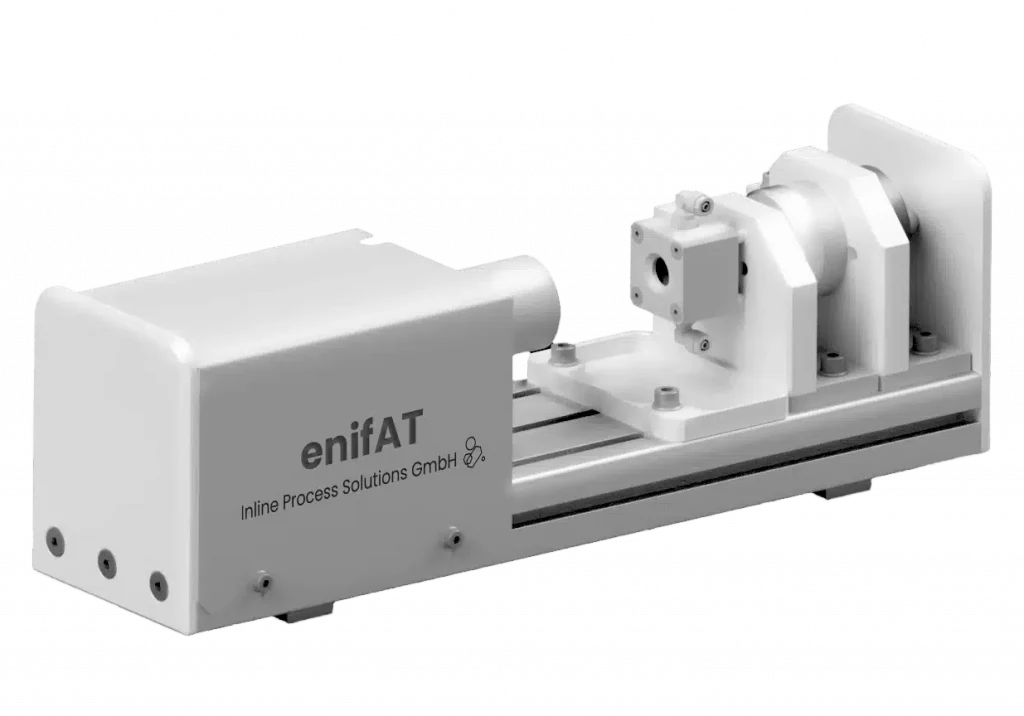

Are you looking for an alternative for your laboratory application? Then our enifAT benchtop device is the right choice for you. Screen suspensions, emulsions or foams to gain an overview of your system. Our proven optical microscope packaged in a slim laboratory setup.

Excellent image quality

Our sensors depict your particle flow in first-class image material - with high contrast, great depth of field and without size distortion.

Simple integration

The sensors use standardized process connections and interfaces. This means that installation is quick and calibration is not necessary.

Robust design

The sensors were developed for harsh industrial conditions and, thanks to their special design, prevent blockages and wetting of the sight glass.

Benefit from a unique combination

Harness the full potential of the combination of hardware and software. AI-based object recognition evaluates images in real time and makes the data directly usable for dynamic process control.

somaWORKSPACE offers you all the necessary functions for control, evaluation, and further processing—directly as a report or control signal.

At the heart of the somaWORKSPACE is AI-based image analysis, which accurately and efficiently detects particles in the image and calculates size and shape parameters with high temporal resolution. Using a new deep learning approach and an innovative training workflow, the analysis is tailored to your application and can be used immediately.

At the heart of the somaWORKSPACE is AI-based image analysis, which accurately and efficiently detects particles in the image and calculates size and shape parameters with high temporal resolution. Using a new deep learning approach and an innovative training workflow, the analysis is tailored to your application and can be used immediately.

Plug & Measure

ANALYZE requires no complex calibration and is pre-trained for a wide range of particle systems and ready for immediate use.

Integrated or standalone

Whether using it in combination with our hardware products or for the evaluation of your own image data - ANALYZE opens up new horizons for your particle analysis.

Precise & fast

ANALYZE enables a high-performance analysis and an exact detection of particle shape even with high phase fractions and overlaps in the image.

Try somaWORKSPACE for your automated image analysis!

We thank you for your strong support

You are currently viewing a placeholder content from Vimeo. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Vimeo. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Bunny Stream. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Wistia. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information