Standard measured variables characterise the condition of the apparatus: temperature, pressure, fill level, volume and mass flows. These measured variables can be tapped very accurately and reliably with little effort.

The situation is different with optical measured variables. Recording these inline poses greater challenges for measurement technology manufacturers and users. Optical measured variables characterise the state of the fluid in the apparatus: composition, turbidity, colour, viscosity, velocity and size of particles.

Optical measuring devices all work on the same principle: a light beam (source: lamp, LED or laser) is sent into the fluid and is altered there (intensity, direction, wavelength, etc.). A detector records the change. The result is a signal or an image.

What are the challenges involved in implementation?

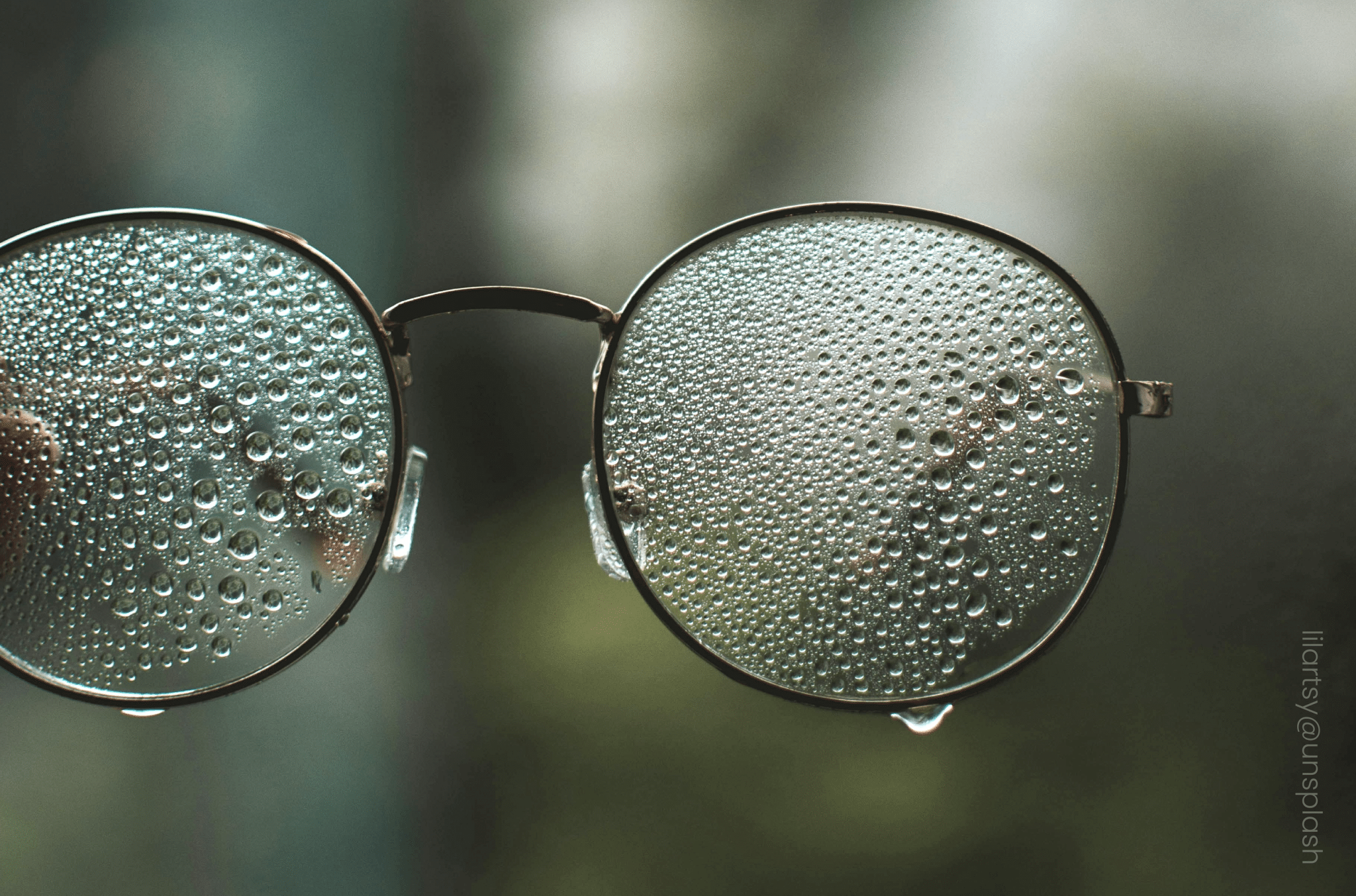

- Viewing windows: The optical access to the device must remain free for the passing light at all times. Fouling or adhering bubbles greatly distort the measurement.

- The sensitive electronics (light source, detector, lenses) must be shielded against high temperatures and humidity. The solution here is often temperature control and inertisation with flushing media.

- The alignment of the light source to the detector, known as the optical axis, must be precise and remain stable even when the device is subject to vibrations.

- Interpretation of data: Signals must be modelled and calibrated, image data must be evaluated and the relevant image information must be forwarded.

- The measurement technology should not influence the flow in the device; invasiveness must be ruled out.

- Particularly tricky when generating images: choosing the right light source. The lighting should be strong enough and homogeneous. At the same time, exposure times must be short to avoid motion blur when fluids are in motion.

- Last but not least, optical components are costly, which means that optical measurement technology cannot be used across the board.

Conclusion

Inline optical imaging measuring devices are packed with innovation and technology. They are particularly useful in processes with high savings potential, in sensitive process steps, in products with strict specifications and in safety-relevant plant components.

Would you like to find out what technical solutions we have found in our sensors to meet these challenges?