In principle, separation technology in the chemical industry is based on the combination and separation of liquid or gaseous material flows. The aim is to concentrate the valuable material, known as the target component, in as pure a form as possible in a single flow. To achieve this, the fact that the target component accumulates particularly well in a flow is exploited.

In a separation apparatus, streams of different phases are mixed together so that enrichment can take place. At the outlet of the separation apparatus, the phases must be separated from each other again. In distillation, this is a liquid and a gaseous stream. In extraction, on the other hand, it is two immiscible liquid streams.

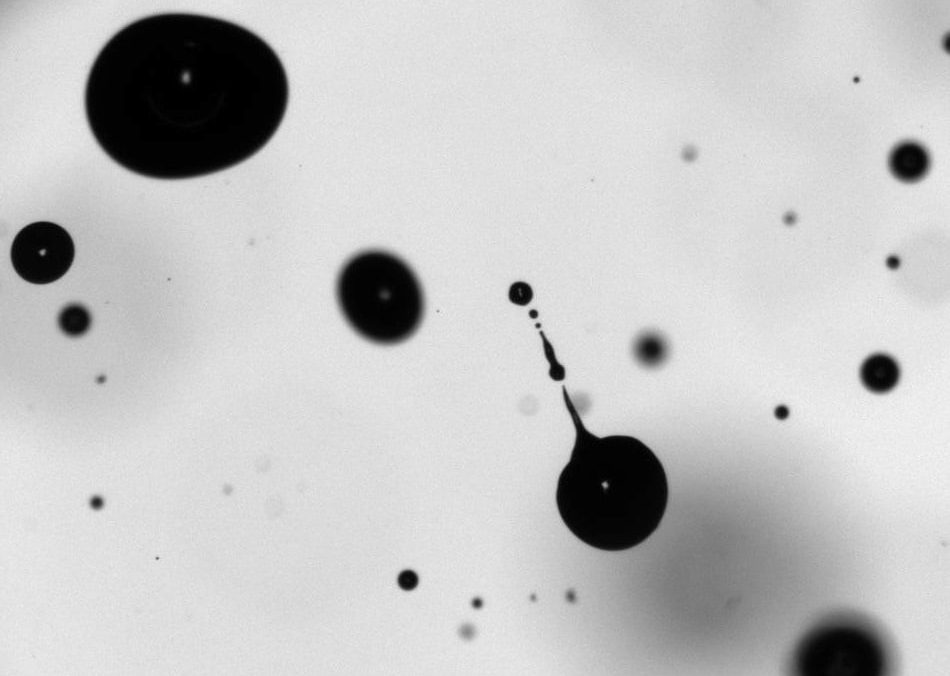

For perfect separation of the phases, the apparatus would have to be infinitely large. However, this is not possible. The compromise: the apparatus has a realistic size, but a small part of the foreign phase is carried along in the stream. This is known as entrainment. This can be gas bubbles or droplets.

So what is the problem with entrainment?

Firstly, entrainment causes a loss of valuable material. The energy requirements of a plant also increase when there is more entrainment. Furthermore, downstream systems such as pumps or compressors can be damaged by entrainment. To prevent this, separators are installed in the outlets of the equipment. However, even these separators reach their limits at some point and ‘break through’, meaning that entrainment can occur unhindered.

An everyday example would be an extractor hood: the extracted cooking fumes contain not only air, but also tiny droplets of water and grease, which are collected in the separator of the extractor hood. Once the separator is full, the fumes are blown back into the kitchen without being cleaned.

Conclusion

Entrainment cannot be prevented and is factored into the cost of plant design. However, if entrainment is greater than calculated, performance losses in the plant and, in the worst case, damage to equipment are to be expected.

Real-time monitoring of entrainment in critical process steps is therefore highly recommended!