Get to know IPS and shape the future of industrial production in plant operation with us.

We value the DIFFERENCE OF PEOPLE.

We deliver EXCELLENT PERFORMANCE.

We are driven by challenges – WE SHAPE THE FUTURE.

TRUST is the basis of our cooperation and we are strong as a team.

We COMMUNICATE – openly and honestly.

Successful collaboration

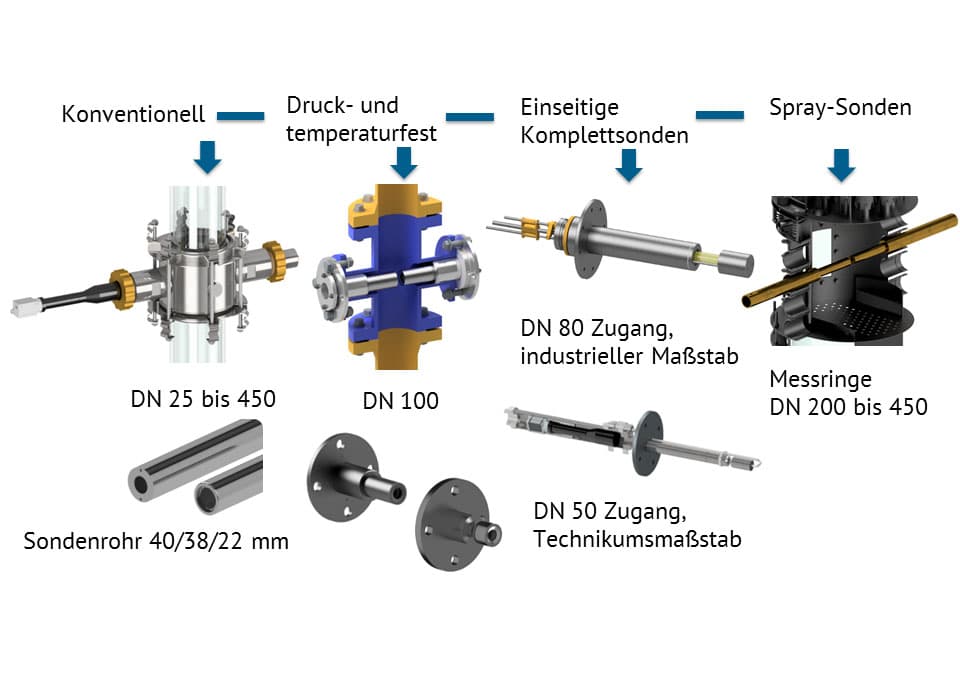

Process optimization based on fluid dynamic measurement of bubbles and droplets

Monitoring of crystallization processes

Characterization of spray dispersion

Characterization of powders in the production process

Optimization of process conditions

Optimization of process conditions in precipitation

Monitoring of crystallization processes

Characterization of dispersion processes

Characterization of powders in the production process

Automated analysis of particle images

Characterization of CFRP dusts

Automated analysis of asbestos fibers

Innovations move us forward

EXIST Research Transfer Funding Phase 2

Increasing the performance and competitiveness of the SOMAWorkspace analysis tool

EXIST Research Transfer Funding Phase 1

Development of industry-relevant MVPs for real-time monitoring of particle flows for crystallisation and spray processes, business development, IP transfer, start-up

Fluid dynamic optimisation of the electrolytic production of green hydrogen

Development of image-based inline sensor technology for use in large-scale electrolysers.

Development of image-based optical sensor technology for process optimisation

Seed financing for expanding the product portfolio, generating initial sales until the break-even point is reached, and establishing a sustainable business model.

VIVET – Association for Innovation in Process Engineering

VIVET develops technologies for fast and efficient process development and production in the chemical and biotechnology industries.

Learn more about

Start of development of sensor technology for bubbles and sprays in collaboration with an international industrial group

Securing seed financing to establish the business model

First successful commissioning of sensor technology in an industrial environment

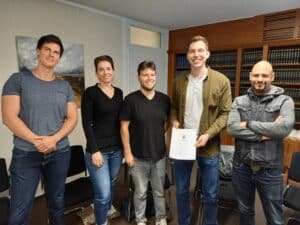

IPS signs transmission and licence agreements with RPTU Kaiserslautern-Landau

Inline Process Solutions GmbH was officially founded in August 2023.

The business idea convinced the jury, who agreed to a two-year sponsorship. The name for the company and product was born: Inline Process Solutions (IPS).

The increased demand for the sensor technology provided the impetus to develop the idea sketch into a fully-fledged business plan.

The European patent EP 3 067 685 B1 was granted.

The prototypes were continuously optimized and field tests in academic and industrial environments were successfully completed.

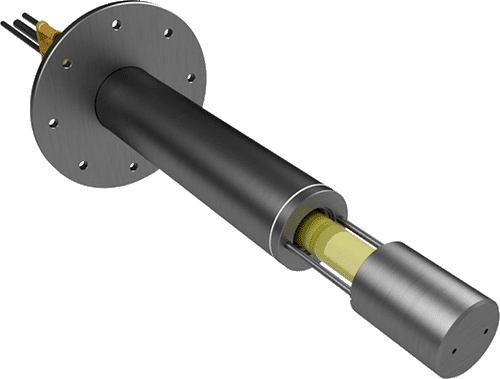

A European patent application has been filed for the one-sided insertion of the sensor technology.

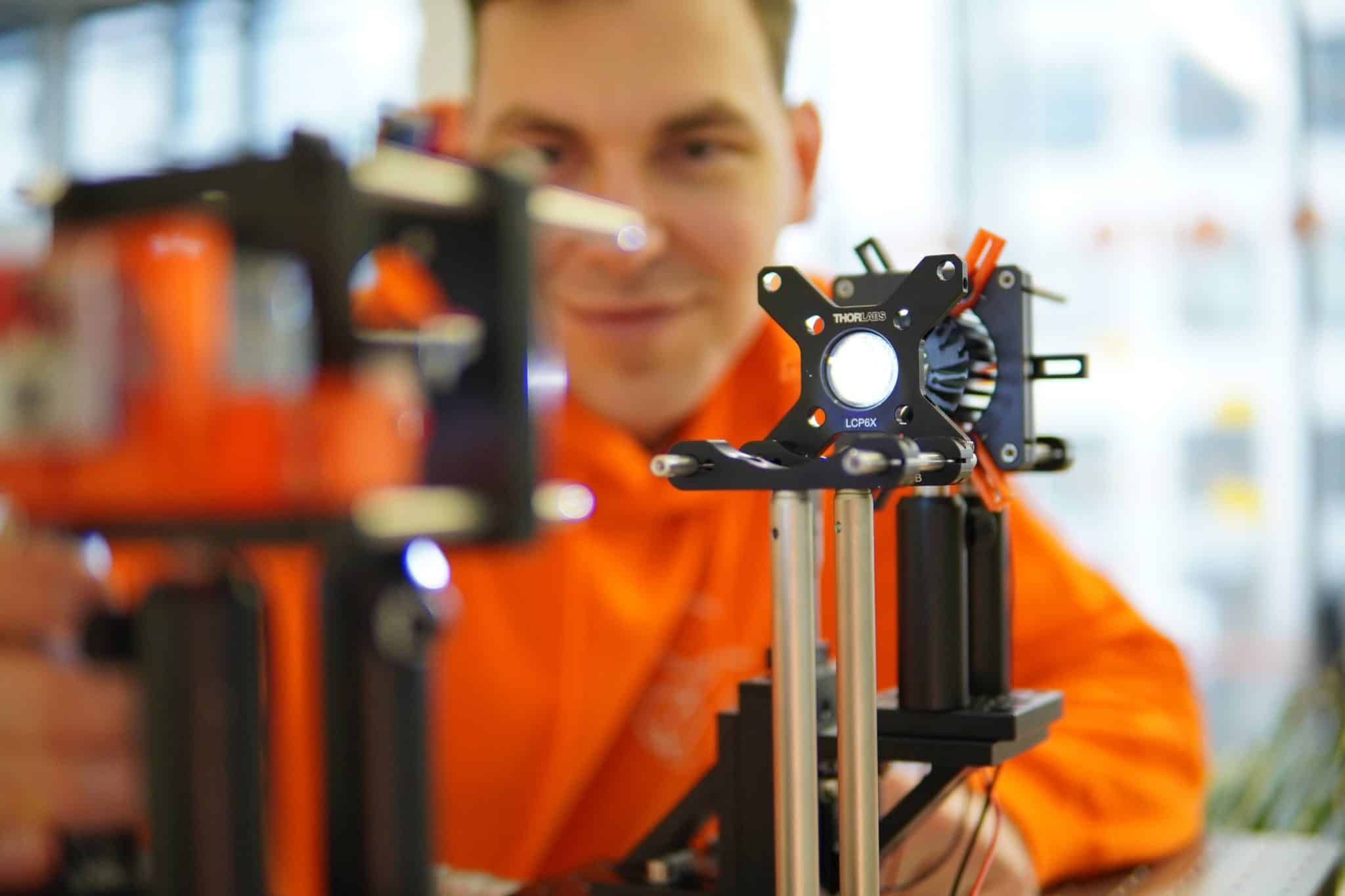

The first step was a measurement setup with two-sided access, which was given the name Optical Multimode Online Probe (OMOP). It was tested in a wide variety of regimes. This was followed by a further development for larger devices and more flexibility with one-sided access.

It all began at the Chair of Process Engineering (Prof. H.-J. Bart) at the Technical University of Kaiserslautern with an attempt to determine droplet sizes in extraction columns in order to improve the modeling and design of this equipment.

You are currently viewing a placeholder content from Vimeo. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Vimeo. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Bunny Stream. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Wistia. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information