We answer your

FAQ

Find answers to frequently asked questions about our inline technology, its applications, integration, and benefits.

Various particle measurement techniques are used for inline measurements in industrial processes, including laser-based methods (e.g., light scattering or diffraction techniques), acoustic measurement principles, and optical imaging methods. While many of these techniques provide only average particle sizes or indirect parameters, they reach their limits when applied to inhomogeneous systems, fluctuating concentrations, or complex particle shapes.

Image-based inline particle measurement technology has proven to be particularly powerful in this context: it detects particles directly within the process, provides real images, and enables the simultaneous determination of particle size, shape, and distribution in real time. Inline Process Solutions develops and manufactures high-resolution image-based inline sensors specifically designed for demanding applications in the chemical and food industries, delivering reliable, process-relevant data for optimal process control.

Various measurement techniques are used to optimize crystallization processes, including offline laboratory analyses, laser-based particle measurement methods, and inline sensors for monitoring process parameters. However, many of these approaches provide only time-delayed or averaged information and offer limited insight into the actual crystal morphology during ongoing processes.

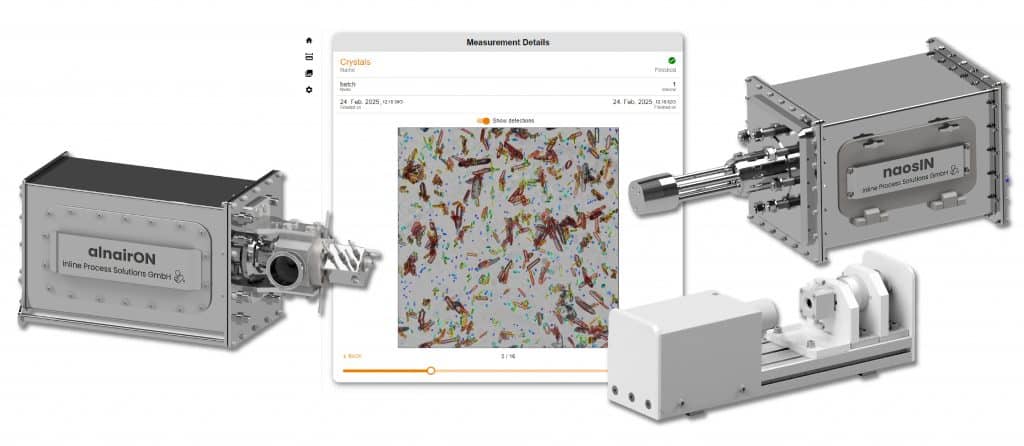

Image-based inline measurement technology enables direct, process-close monitoring of crystals and continuously delivers real image data on crystal size, shape, and distribution. With the inline sensors alnairON and arkturIN, Inline Process Solutions offers powerful solutions specifically designed for crystallization processes, supporting targeted and well-founded optimization of crystal growth, product quality, and process stability.

Various measurement techniques are available for the characterization of sprays and droplets, including laser-based methods such as phase Doppler anemometry and light scattering techniques, as well as camera-based systems. However, many of these approaches are designed for idealized conditions and often provide only limited or indirect information under real process conditions.

Image-based inline particle measurement technology captures sprays and droplets directly within the process and enables real-time analysis of individual droplets in terms of size, shape, and distribution. The inline sensor naosIN from Inline Process Solutions is specifically designed for these applications and delivers robust, high-resolution measurement data, enabling reliable monitoring and optimization of spray and droplet processes.

Yes, powders can be measured online directly within the running process; however, the choice of measurement method strongly depends on particle size, concentration, and process conditions. Common techniques such as laser diffraction provide average particle size values but quickly reach their limits when dealing with heterogeneous or agglomerated powders.

Image-based inline particle measurement technology is particularly powerful, as it detects individual powder particles directly and delivers real-time data on particle size, shape, and distribution. With the alnairON and arkturIN sensors, Inline Process Solutions offers robust solutions specifically developed for powder measurement in industrial processes, enabling precise, process-close monitoring.

Chemical production requires sensors that deliver reliable measurement data directly within the process. In addition to laser-based or acoustic methods, image-based inline sensors have proven to be particularly powerful, as they detect particles directly and provide real-time data on particle size, shape, and distribution.

The sensors from Inline Process Solutions, including alnairON and arkturIN, are specifically designed for the harsh conditions of chemical production: robust, ATEX-certified, and resistant to high temperatures and pressures. This enables precise and safe process monitoring in demanding industrial environments.

Both technologies have their strengths; however, for many industrial applications, image-based inline particle measurement technology offers clear advantages. Laser-based methods (e.g., light scattering or diffraction) often provide only average values or indirect particle size information and quickly reach their limits when dealing with complex particle shapes, agglomerates, or inhomogeneous systems.

Image-based systems detect particles directly and in real time. In addition to particle size, they provide information on particle shape and size distribution, enabling detailed, process-close analysis. The sensors from Inline Process Solutions, such as alnairON, arkturIN, and naosIN, are also robust, ATEX-certified, and designed to withstand high temperatures and pressures, making them ideal for demanding applications in chemical and food production.

Insights and Expertise in our Inline Measurement Technology

Blog Posts

Never lose sight of the big picture – inline use of optical measurement methods

Updates from Our Company and Upcoming Events

News & Dates