In order to monitor production processes in chemical and food technology, measurement data is collected at many points. This involves detecting the physical or chemical properties of the process streams or recording the status of individual devices. All these measured variables together determine the status of the process and are referred to as process analysis technology – PAT for short.

And what is PAT needed for?

These measured variables are essential for operating a complex chemical plant, as many parameters are not set manually but controlled in a control room. The operating team also relies on the measurement data to monitor and optimise the plant.

A general distinction is made between four types of measurement data acquisition:

OFFLINE

The classic method: take a sample, send it to the laboratory and wait for the results.

ATLINE

In principle, the same as offline, except that the sample analysis takes place on a device located close to the plant. Advantage: waiting time is reduced and the results are available more quickly.

ONLINE

Bringing the measurement technology closer to the process in order to avoid sampling. Online measurement methods are usually implemented via a sample loop, which extracts the process medium from the apparatus, measures it and returns it. This can be considered a type of real-time measurement. However, there is a risk that the sample loop will become clogged over time and distort the measurement.

INLINE

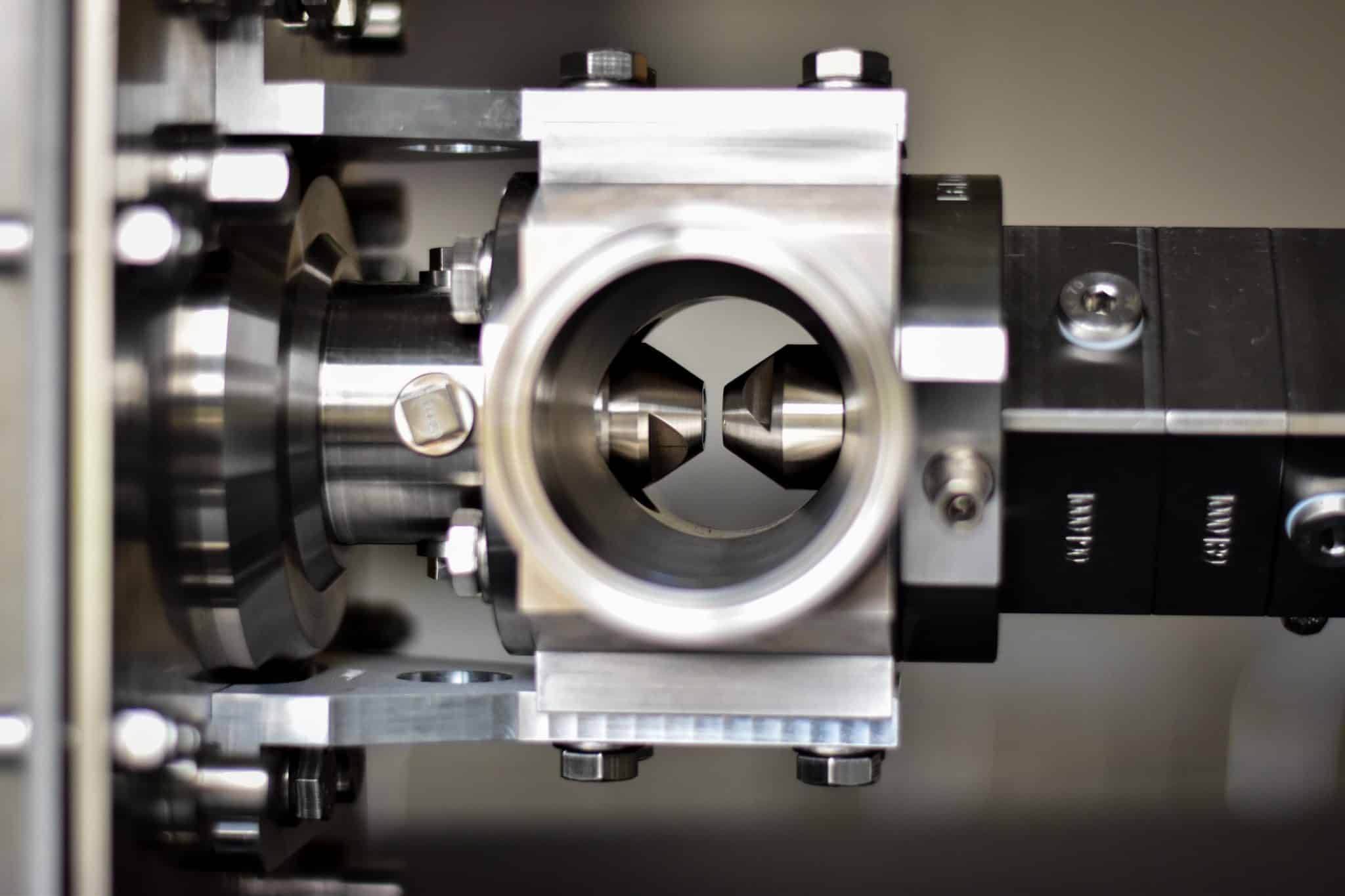

The supreme discipline, where the measuring device is located directly in the plant and measures at the point of action. This means real real-time data without distortion.

But why aren’t all measurements performed inline? Measurement variables that are easy to detect inline include temperature and mass flow. However, some measurement variables, such as concentration or particle size, cannot be determined inline so easily. The reason: the measurements are very complex, the measuring instrument is sensitive and cannot be integrated into the harsh process conditions.

For this reason, particle size is currently still often measured offline!

The result:

- No real-time data

- No possibility to counteract incorrect particle size in the process

- No data for non-samplable particles (droplets, bubbles)

And unfortunately, this often results in:

- Unwanted plant downtime

- Disposal of failed products

- Trial and error when troubleshooting in the process

Therefore: Measure particle sizes inline!

Save money and valuable time!

How? We’ll show you!