ANALYZE

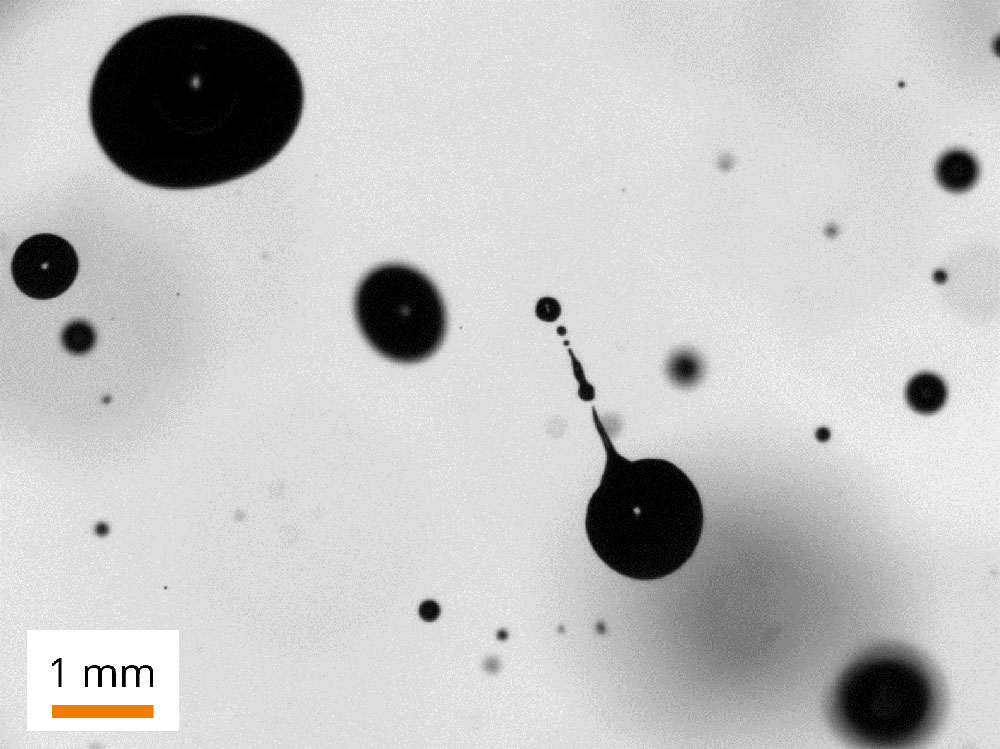

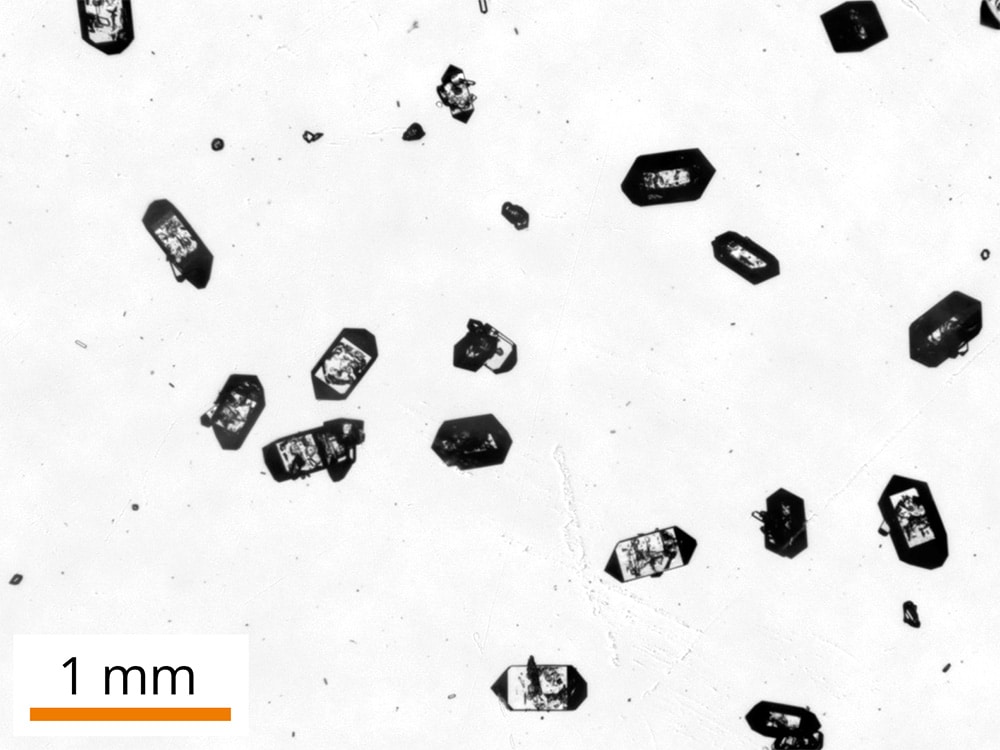

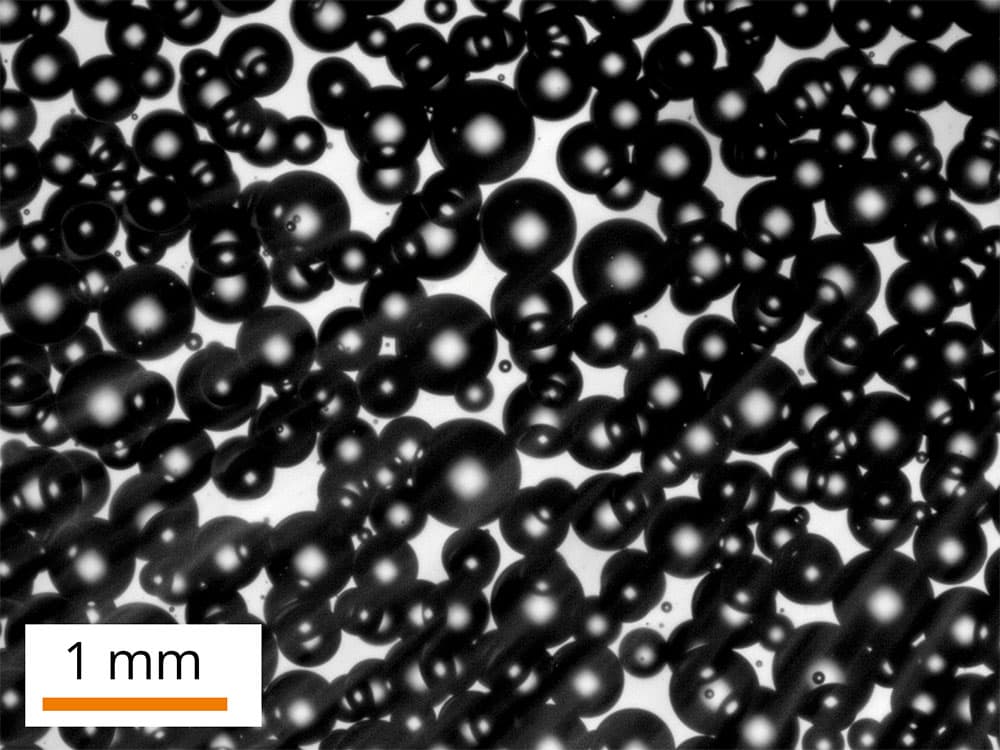

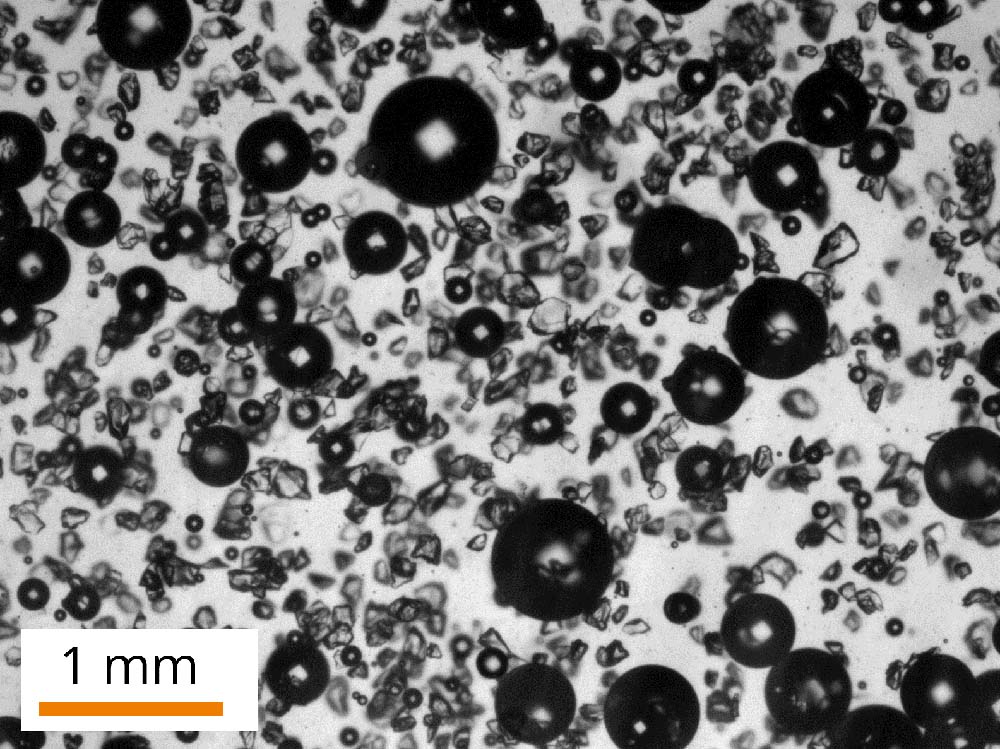

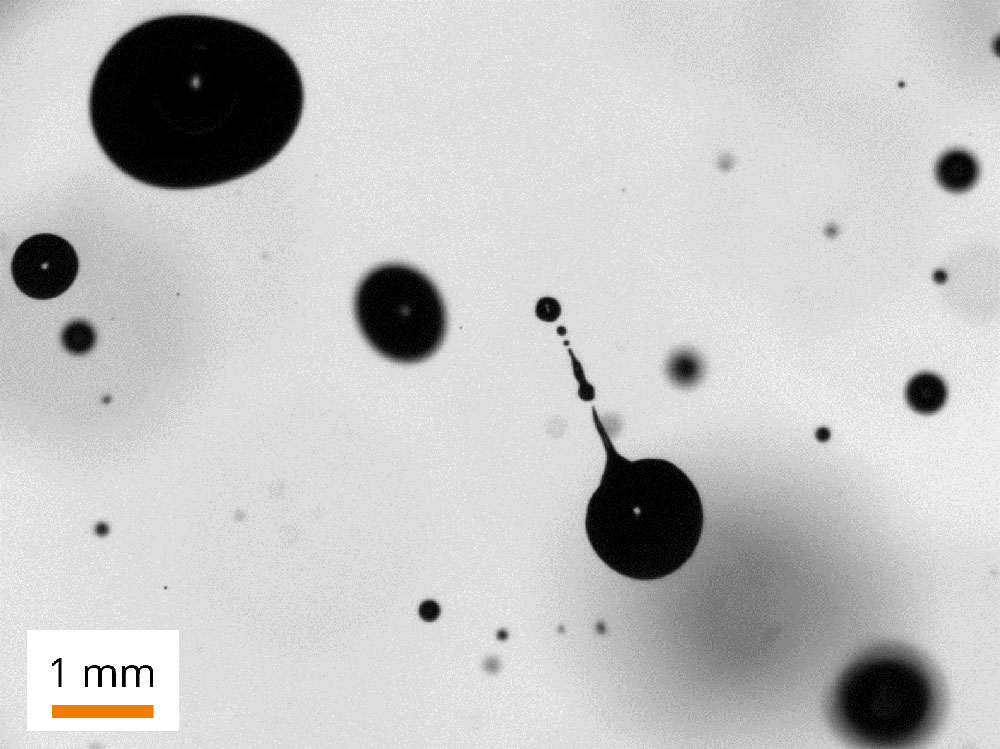

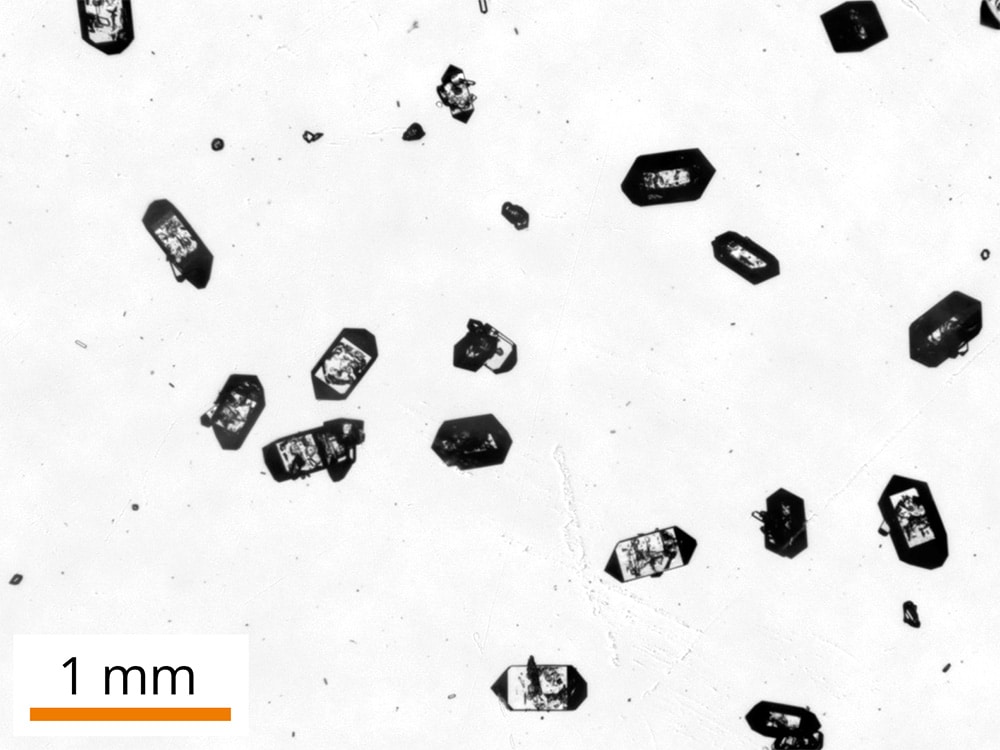

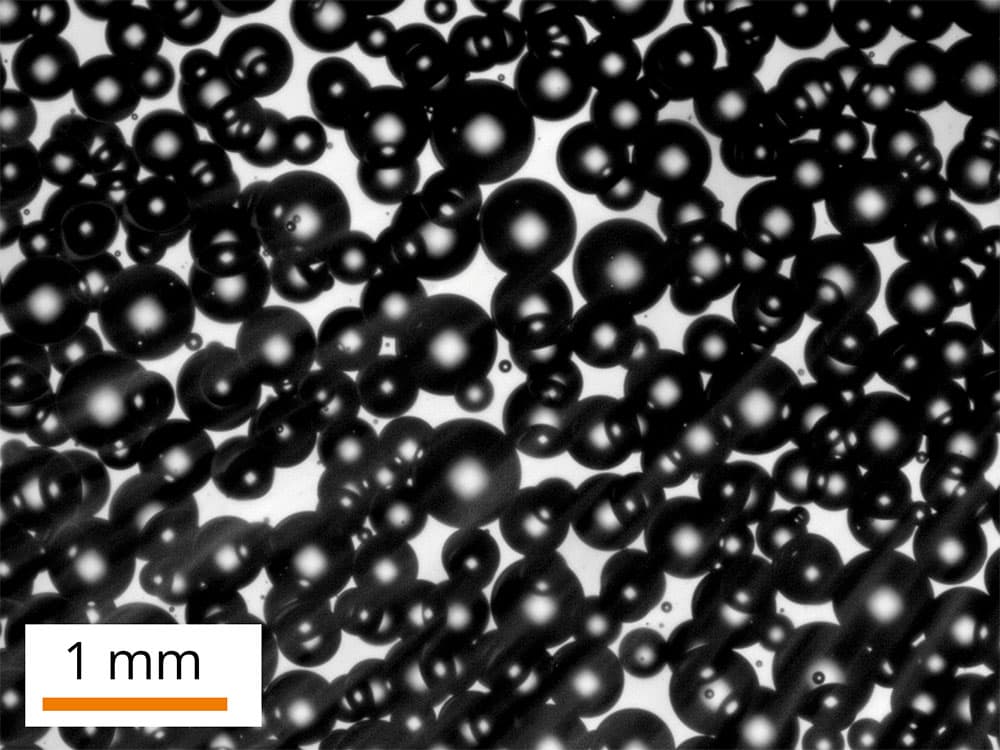

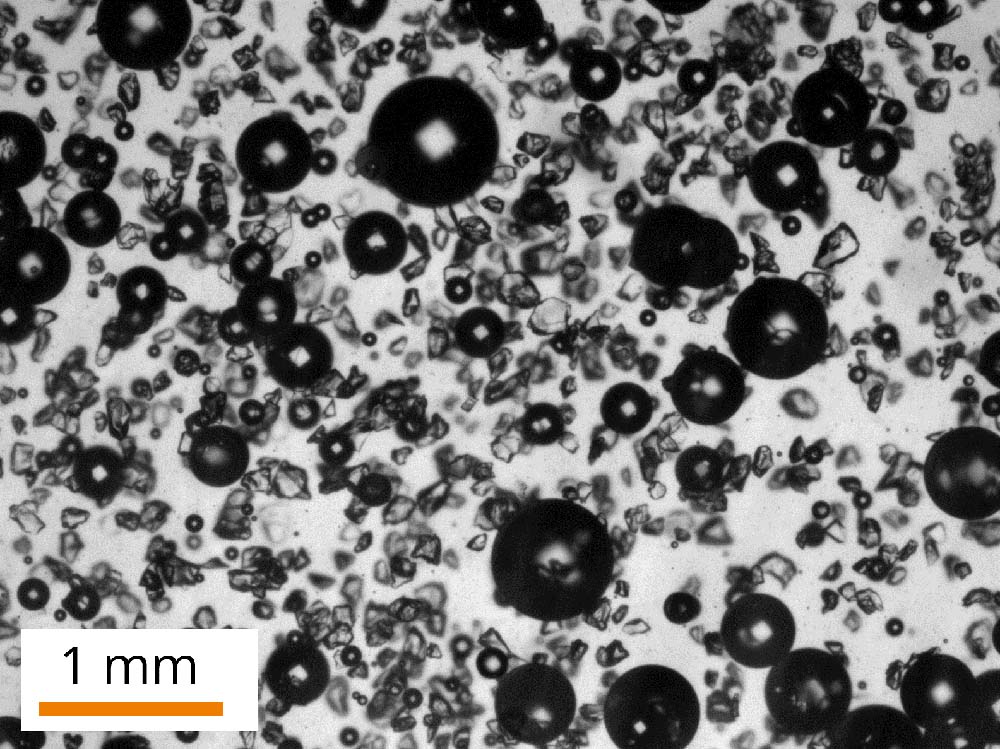

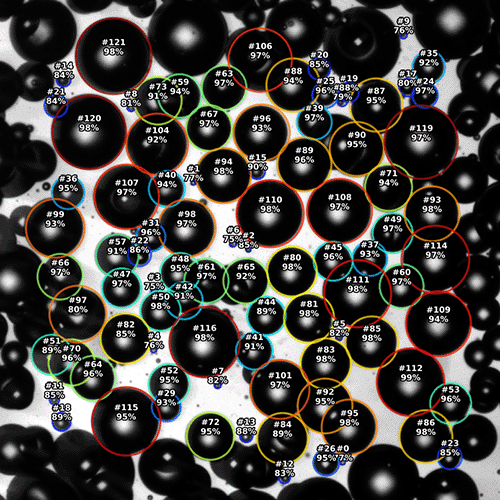

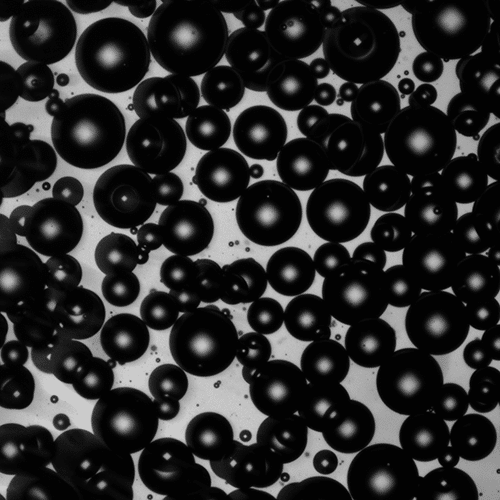

Due to the high quality of the experimental image data, we have excellent training data, which we use for our dep learning algorithm, so that our software is significantly more flexible, faster and, moreover, more accurate in the analysis and evaluation of the flow processes.